The BMW E46 is often cited as one of the most balanced BMWs ever produced. With its rear-wheel-drive architecture, near 50/50 weight distribution and sophisticated running gear for its time, it had an excellent base on paper.

However, with hindsight and experience, one thing is clear: the E46 chassis is not absolutely rigid. It is sufficient rigid for original use, but it deforms, in a measurable way, under dynamic stress.

Understanding these deformations helps us understand why some modifications really work, and why others are purely aesthetic.

The BMW E46 chassis: a semi-rigid structure, not a monolithic block

The E46 chassis is a self-supporting steel shell, composed of :

- longitudinal beams

- of sleepers

- suspension mounting points (turrets, cradles)

- intentionally deformable zones (safety)

Unlike a tubular chassis or a modern carbon shell, the assembly is not perfectly rigid. And that's not a defect: a certain flexibility is needed to filter out constraints and preserve comfort.

The problem occurs when :

- the car ages (metal fatigue),

- increased demands (modern tires, dynamic driving),

- some areas are working beyond what they were designed for.

What happens physically in a bend: the reality of effort

When an E46 enters a bend, several phenomena occur simultaneously :

- Lateral load transfer

Weight shifts to the outer wheels. - Vertical force on shock absorbers

The outer shock absorber compresses sharply. - Horizontal force on turrets

The strut exerts a thrust outward of the cash register.

👉 Front turrets therefore tend to move away from each other.

This movement is small (a few tenths of a millimetre), but dynamic:

- it is fast,

- repetitive,

- asymmetrical (left ≠ right).

And above all: modifies suspension geometry in real time.

Why chassis deformation is a behavioral problem

A suspension is designed to operate in a given geometry:

- camber

- hunting

- pivot angle

- parallelism

If the anchor points move :

- the wheel is no longer working at the intended angle,

- the tire's contact patch varies,

- steering response becomes less predictable.

The driver then feels :

- a blur when entering bends,

- less clear direction,

- constant corrections in support,

- a car that seems to be “working” under him.

It's not a pure loss of adhesion, but loss of mechanical consistency.

The front crossbar: a structural role, not a cosmetic one

A front grab bar connects directly to the two shock-absorber turrets.

Its physical role is simple:

- transform two independent points into a united whole,

- prevent turrets from spreading apart under load.

Real mechanical effect

- reduced lateral deformation,

- maintenance of suspension geometry,

- reduced delay between steering wheel action and chassis reaction.

Impact felt

- more precise direction,

- sharper corner entry,

- better reading of the available grip,

- sensation of “blockiness” at the front.

It's not a question of increasing maximum grip, but of achieve this adhesion in a more stable and reproducible way.

Front crossbar BMW E46

Optimize the chassis rigidity of your BMW E46 with this front anti-roll bar. It limits deformation of the shock towers, improves steering precision, reduces body roll and enhances cornering stability, both on the road and in sporty driving.

Why the rear of the E46 also works (and why it's less talked about)

At the rear, the problem is different but just as real.

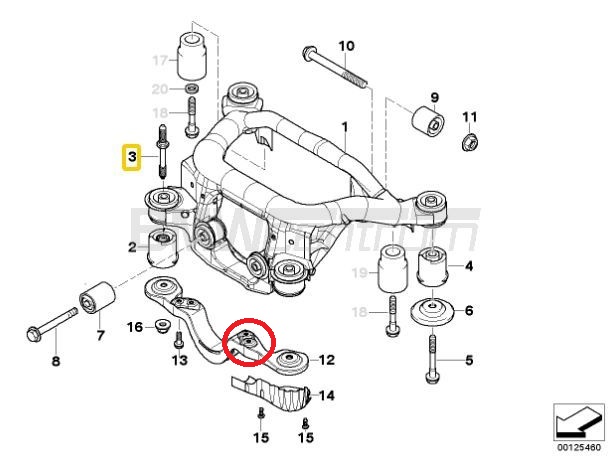

The E46 uses a multi-link rear axle, attached to the body via a cradle. In support :

- motor torque,

- lateral forces,

- suspension reactions

create torsional stresses on the rear of the hull.

Even without going as far as the known problems of cradle cracking, we observe :

- slight longitudinal bending,

- parasitic movements between the two sides of the rear axle.

The rear anti-roll bar: a global balancing role

The rear bar doesn't work like the front. It acts primarily on :

- the rear axle consistency,

- left/right symmetry in support,

- stability on exiting bends.

Mechanical effects

- reduction in local torsion,

- better transmission of forces to the hull,

- smoother rear-end response.

Effects felt

- more stable car at high speed,

- cleaner transitions,

- more neutral behavior,

- coherent front/rear feel.

It's often the part that makes it clear that the chassis works as a whole.

Reinforced rear crossbar for BMW E46

Stiffens the rear end of your E46 for a more precise, more stable and more stable car. Ideal for dynamic roads, mountain passes, daily sports and trackdays.

Front only, rear only or both: a physical logic

| Configuration | Main effect |

|---|---|

| Front only | Steering precision |

| Rear only | Stability and neutrality |

| Front + rear | Overall chassis coherence |

Installing only the front improves precision, but may accentuate the offset with a softer rear.

Installing both allows you to rebalancing stress flows throughout the structure.

Compatibility and installation on BMW E46

- Compatible with all engines (4cyl, 6cyl, diesel, petrol)

- Sedan, coupé, touring, convertible

- Reversible mounting

- No irreversible chassis modifications

The improvement comes from respect for the original structure, not its transformation.

Conclusion: Intelligent stiffening without distorting the BMW E46

The BMW E46 doesn't need to be “corrected”.

It deserves to be mechanically accompanied, taking into account :

- material fatigue,

- modern constraints,

- the actual physics of the chassis.

Front and rear lap bars are neither gadgets nor miracles.

They are mechanical consistency tools, which allow the chassis to work as it should always have done under severe duress.

A more legible, more consistent, more predictable chassis -

without compromising the E46's DNA.